Introduction:

Blowers play a crucial role in the functionality and performance of ventilators, delivering the necessary airflow for respiratory support. Ensuring the optimal operation of these blowers is essential for patient care and safety. One effective method of testing the performance of ventilator blowers is by utilizing flow meters. In this article, we will explore how flow meters enable biomedical engineers to assess the flow vs. pressure characteristics of blowers used in ventilators, providing valuable insights into their functionality.

Understanding Flow vs. Pressure Characteristics:

The flow vs. pressure characteristic of a blower is a critical aspect that determines its performance and effectiveness in delivering airflow during ventilation. This characteristic curve illustrates the relationship between the blower’s airflow capacity and the corresponding pressure generated at various flow rates. Testing this characteristic helps assess the blower’s efficiency, stability, and ability to deliver the required airflow under different conditions.

The Role of Flow Meters:

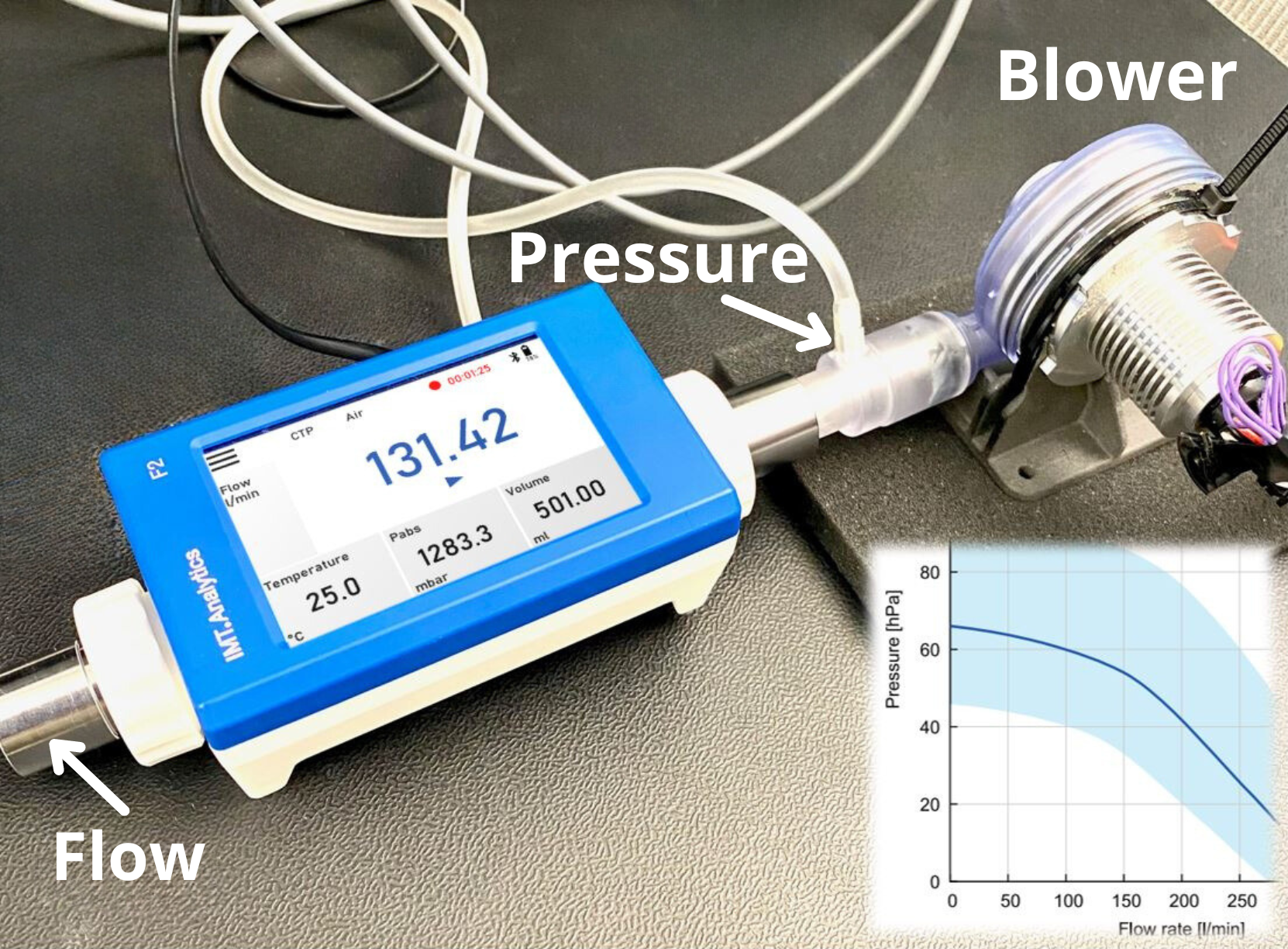

Flow meters are invaluable tools in testing blowers for ventilators, offering precise measurement and analysis of airflow and pressure. They enable manufacurers to evaluate the flow vs. pressure characteristics, providing essential data to assess blower performance. Flow meters measure the flow rate and associated pressure, allowing for a comprehensive understanding of the blower’s behavior across various operating conditions.

Assessing Flow vs. Pressure Characteristics:

Using a flow meter, engineers can conduct tests to determine the flow vs. pressure characteristics of ventilator blowers. The flow meter measures the airflow generated by the blower at different pressure settings. By systematically adjusting the back pressure and recording the corresponding flow rates, a characteristic curve can be established, showcasing the blower’s performance throughout its operational range.

Benefits of Testing Flow vs. Pressure Characteristics:

Testing the flow vs. pressure characteristics offers several benefits in evaluating blower performance. It helps identify any deviations from expected behavior, ensuring that the blower operates within specified parameters. Additionally, it enables manufactuers to verify the blower’s ability to deliver consistent airflow at different pressure levels, which is critical for maintaining proper ventilation and patient comfort.

Optimizing Ventilator Performance:

By utilizing flow meters to test blowers, engineers can optimize ventilator performance. The insights gained from assessing flow vs. pressure characteristics enable informed decision-making in selecting appropriate blower settings and adjustments to ensure optimal airflow delivery. This contributes to enhancing patient care, improving ventilation efficiency, and ensuring the reliability of ventilator systems.

Conclusion:

Testing blowers for ventilators is crucial to ensure their reliable and efficient performance. Flow meters provide a valuable tool for assessing the flow vs. pressure characteristics of these blowers, enabling manufacturers to gain insights into their functionality and performance. By leveraging flow meters during testing, healthcare providers can optimize ventilator performance, maintain proper ventilation parameters, and ultimately enhance patient outcomes. The use of flow meters represents a significant advancement in quality control and preventive maintenance, supporting the continuous improvement of ventilator technology and patient care.

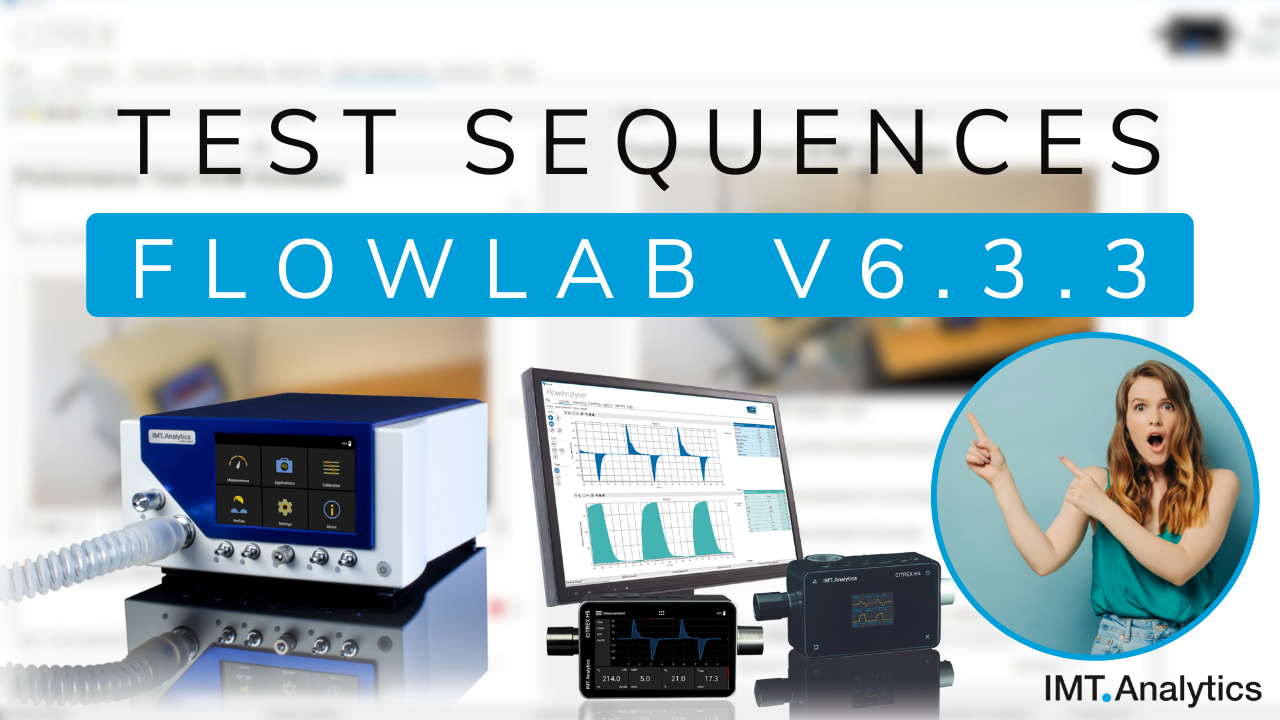

Revolutionize Your Medical Device Testing and Calibration with IMT Analytics’ FlowLab software with test sequence

Test Sequences are not just a tool; they are your gateway to unparalleled control and customization. Imagine tailoring testing or calibration procedures to meet the