Introduction:

In 1993, the Occupational Safety and Health Administration (OSHA) and the Food and Drug Administration (FDA) collaborated to develop the Anaesthesia Apparatus Checkout Recommendations. These recommendations provide crucial guidelines for conducting thorough testing and checks on ventilators and anesthesia gas delivery systems. By adhering to these recommendations, healthcare facilities can ensure the safety and efficiency of anesthesia procedures, safeguarding patient well-being. In this article, we will explore the significance of ventilator and anesthesia gas testing as outlined in the OSHA FDA Anaesthesia Apparatus Checkout Recommendations of 1993.

- Ventilator Testing:

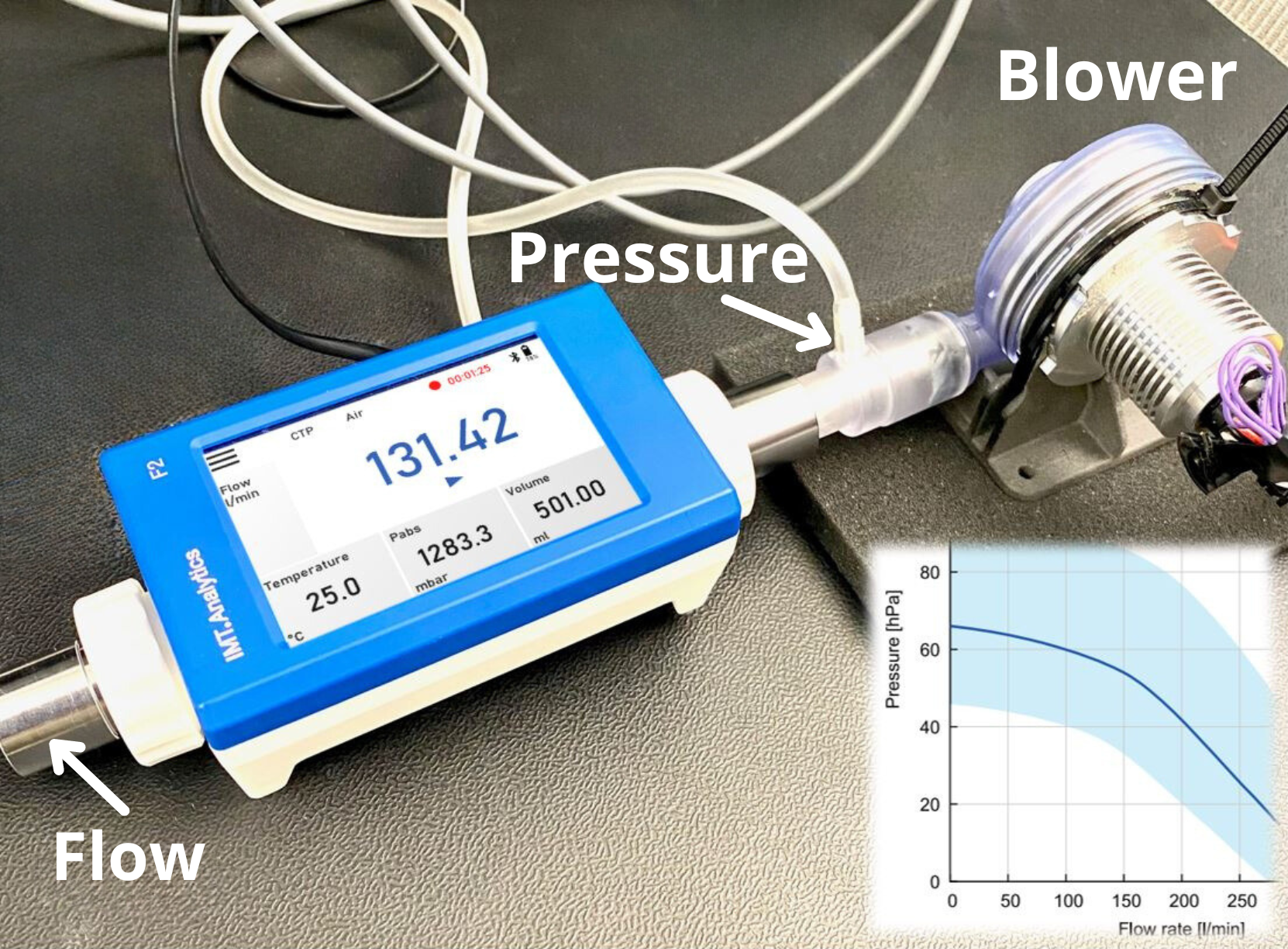

Ventilators are vital life-support devices used in various medical settings, including surgical procedures. The OSHA FDA recommendations highlight the importance of rigorous testing to verify the proper functioning of ventilators. This includes evaluating parameters such as pressure, volume, oxygen concentration, and alarm systems. By conducting comprehensive ventilator testing, healthcare providers can ensure accurate and reliable delivery of respiratory support, minimizing the risk of complications during anesthesia. - Anesthesia Gas Delivery System Testing:

Anesthesia gas plays a critical role in maintaining patient comfort and safety during surgical procedures. The OSHA FDA recommendations emphasize the need for thorough testing of anesthesia gas delivery systems. This involves evaluating the integrity of gas supply lines, checking for leaks, and verifying the accuracy of flow meters and vaporizers. By ensuring the proper functioning of the anesthesia gas delivery system, healthcare professionals can provide precise and controlled administration of anesthesia agents, optimizing patient care. - Routine Maintenance and Calibration:

To maintain the accuracy and reliability of ventilators and anesthesia gas delivery systems, routine maintenance and calibration are crucial. The OSHA FDA recommendations stress the significance of following manufacturer guidelines for maintenance intervals, cleaning procedures, and calibration checks. Regular maintenance and calibration help identify and address any deviations or malfunctions promptly, ensuring consistent performance and enhancing patient safety. - Documentation and Record-Keeping:

Accurate documentation of ventilator and anesthesia gas testing is vital for compliance and quality assurance. The OSHA FDA recommendations highlight the importance of maintaining detailed records of testing procedures, results, and any corrective actions taken. Proper documentation enables traceability, aids in audits, and serves as evidence of adherence to recommended guidelines. It also facilitates the identification of patterns or trends related to equipment performance and maintenance. - Training and Competency:

To effectively implement the OSHA FDA recommendations, healthcare professionals involved in anesthesia care should receive proper training and demonstrate competency in conducting ventilator and anesthesia gas testing. Training programs should cover the principles of equipment testing, troubleshooting, and interpretation of results. Competent personnel can confidently perform testing procedures, ensuring accurate assessments of equipment functionality and promoting patient safety.

Conclusion:

Adhering to the OSHA FDA Anaesthesia Apparatus Checkout Recommendations of 1993 is essential for healthcare facilities to maintain the safety and efficiency of ventilators and anesthesia gas delivery systems. Through rigorous testing, routine maintenance, and proper documentation, healthcare professionals can identify and address potential issues, minimizing the risk of adverse events during anesthesia procedures. By investing in training and competency development, healthcare organizations promote a culture of excellence and ensure that personnel are equipped with the necessary skills to conduct comprehensive equipment testing. Ultimately, following these recommendations enhances patient safety and contributes to the delivery of high-quality anesthesia care.