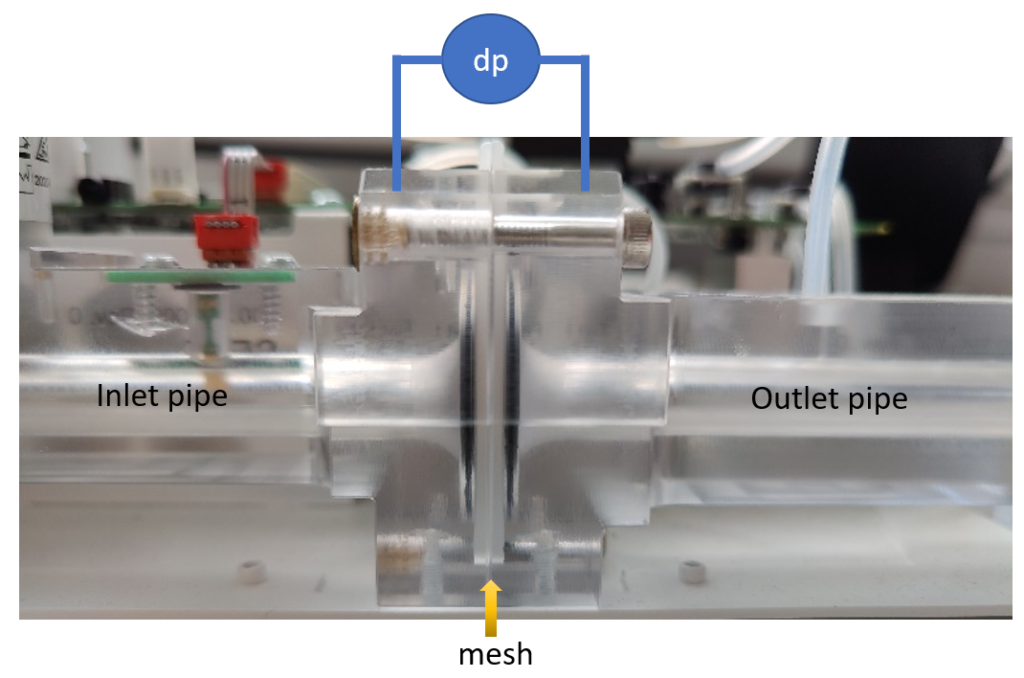

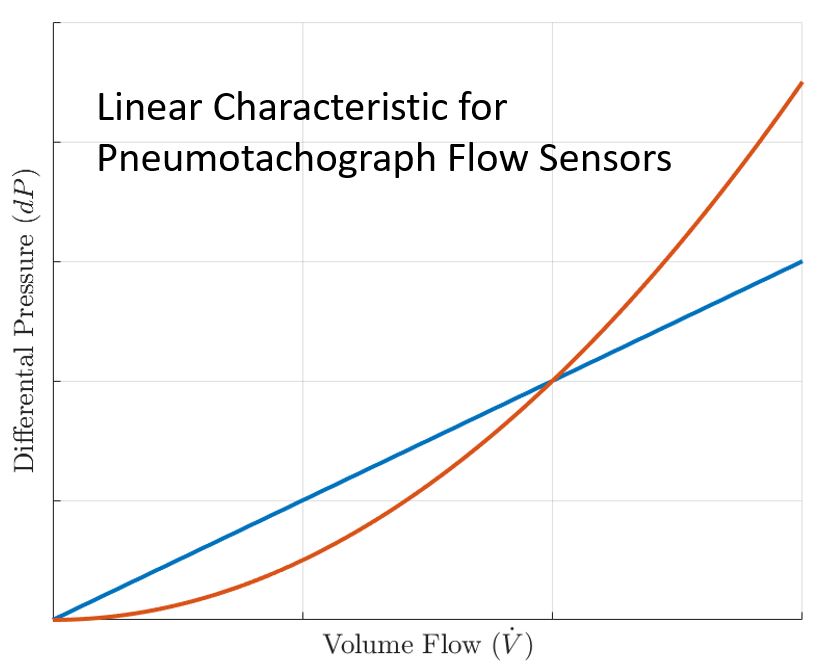

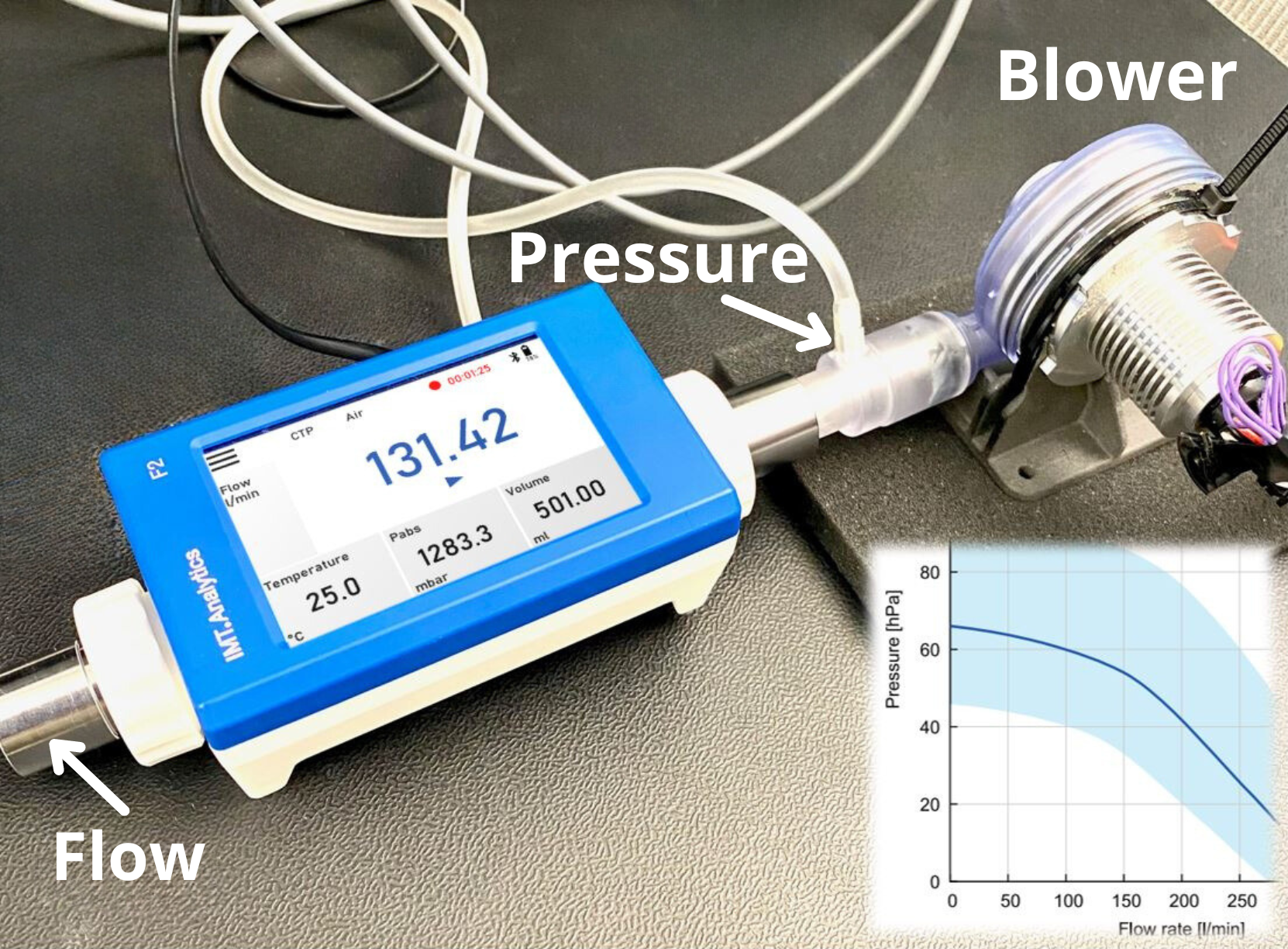

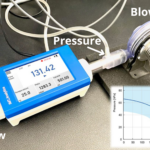

A pneumotachograph flow sensor converts the flow of gases through it into a proportional signal of pressure difference on either side of a central mesh whose design ensures a signal linearity over a range of flow rates. Using a differential pressure sensor, the pressure drop over the mesh is measured. With this measurement and a prerecorded characteristic line, the flow through the channel can be calculated. Finally, a sophisticated physics model is required to correct the flow to the current gas conditions, such as gas type, temperature, or pressure.

Advantages of using a mesh

Having linear characteristics is desirable also in a measuring device. It simplifies the characteristic line because the flow is directly proportional to the differential pressure. Therefore, to calculate the characteristic line as a function, only one parameter must be determined. Furthermore, the resolution is the same for low flows and high flows. Whereas a quadratic characteristic has much worse resolution for low flows than for high flows. This constant resolution of the characteristic line has a few benefits. For example, the influence due to sensor drift is small. Also, a huge range of flows can be measured accurately. Finally, the mesh has the advantage of a small form factor and can therefore be more easily integrated in a system.