Introduction:

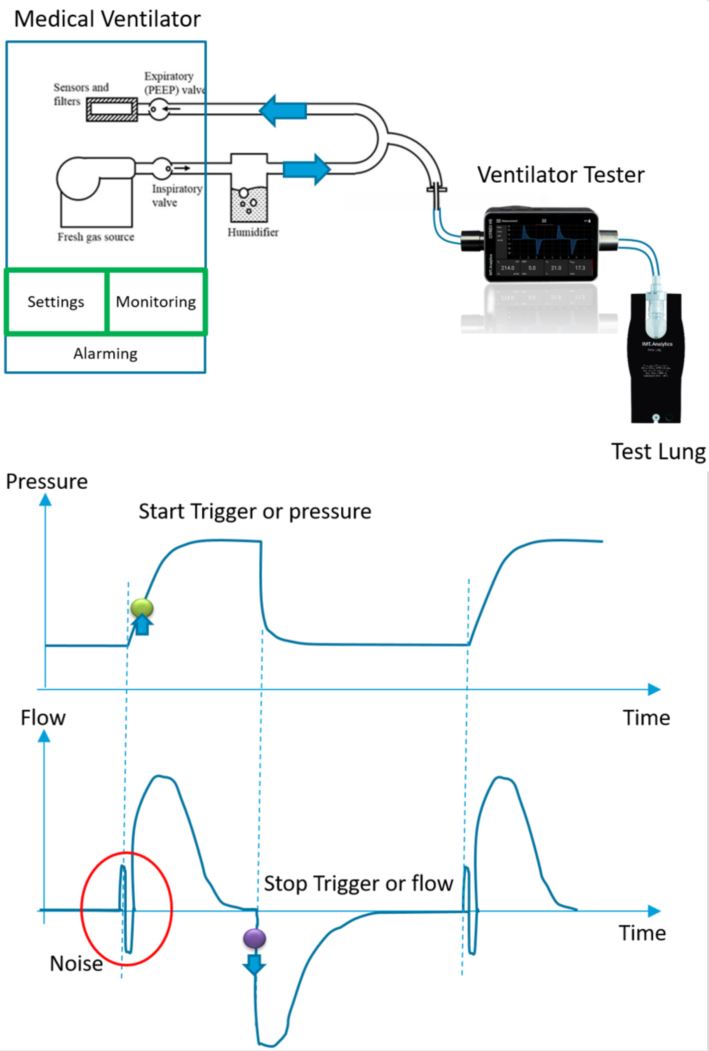

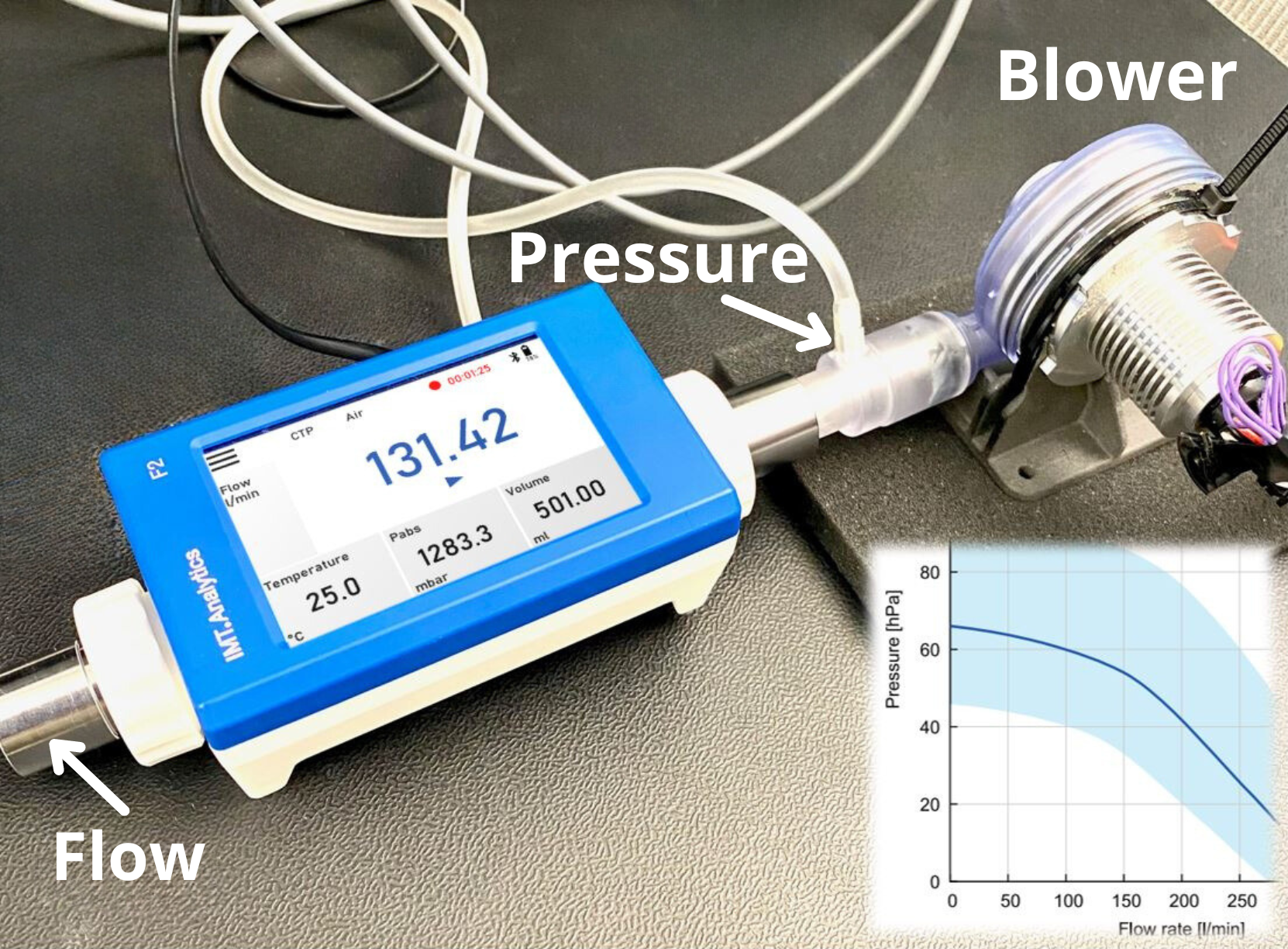

In the critical field of medical ventilation, accurate and reliable measurement of respiratory parameters is paramount. To ensure the optimal functioning of a medical ventilator, rigorous testing is required. A ventilator tester or gas flow analyzer plays a vital role in independently verifying the settings and monitoring system of a ventilator. However, the accuracy of these measurements heavily relies on the analyzer’s ability to detect the breath cycle of the ventilation system. In cases where noisy signals are provided by the ventilator, breath detection can become unreliable, potentially leading to false results. In this article, we will explore the significance of reliable breath detection and the importance of setting start and stop conditions on different signals, enabling gas flow analyzers to measure respiratory parameters with utmost precision.

The Significance of Respiratory Parameters:

Medical ventilators play a critical role in assisting patients who have compromised respiratory functions. To ensure the optimal ventilation of these patients, it is crucial to accurately measure respiratory parameters. Parameters such as inspiration (Pinsp) and expiration (PEEP) pressure, in- and expiratory tidal volumes (Vte, Vti), and breath rate (RR) provide valuable insights into the performance of a ventilator. Verifying these parameters is essential for ensuring that the ventilator is delivering the prescribed therapy effectively and that patient safety is not compromised.

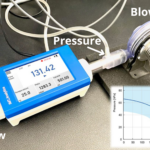

The Role of a Gas Flow Analyzer:

A gas flow analyzer serves as a reliable tool for independently testing ventilators. It allows healthcare professionals to verify the settings and monitoring system of the ventilator, ensuring its compliance with safety and performance standards. However, accurate measurement of respiratory parameters heavily relies on the analyzer’s ability to detect the breath cycle of the ventilation system. If noisy signals are provided by the ventilator, the gas flow analyzer may fail to reliably detect breaths, leading to inaccurate or false measurements.

The Importance of Reliable Breath Detection:

To overcome the challenges posed by noisy signals, it is crucial to establish reliable breath detection mechanisms within the gas flow analyzer. This ensures that the analyzer accurately identifies the start and stop of each breath, allowing for precise measurement of respiratory parameters. By detecting the breath cycle effectively, potential errors caused by irregular or inconsistent signals from the ventilator can be minimized.

Setting Start and Stop Conditions on Different Signals:

One effective approach to achieve reliable breath detection is to set start and stop conditions on different signals. For instance, setting the start inspiration condition at the rising edge of the pressure signal and the stop condition at the falling edge of the flow signal can yield accurate results. This approach leverages the strengths of both signals, enabling the gas flow analyzer to detect breaths more reliably. By considering multiple signal sources, the tester enhances its ability to measure respiratory parameters accurately, even in the presence of noisy signals.

Ensuring Your Ventilator Tester Offers Such Capabilities:

When selecting a ventilator tester, it is essential to ensure that it offers the capabilities mentioned above. The ability to set start and stop conditions on different signals enhances the reliability of breath detection, leading to more accurate measurement of respiratory parameters. By investing in a test equipped with this feature, healthcare professionals can have confidence in the integrity of their ventilator testing processes.

Conclusion:

Accurate measurement of respiratory parameters is crucial for ensuring the optimal functioning of medical ventilators and patient safety. Gas flow analyzers play a vital role in independently verifying the settings and monitoring system of ventilators. However, the presence of noisy signals can hinder reliable breath detection, potentially leading to inaccurate results. By setting start and stop conditions on different signals, such as the rising edge of the pressure signal and the falling edge of the flow signal, testers can enhance breath detection reliability and provide precise measurement of respiratory parameters. When selecting a ventilator tester, it is essential to prioritize these capabilities, ensuring the integrity of the testing process and ultimately contributing to improved patient care and safety.